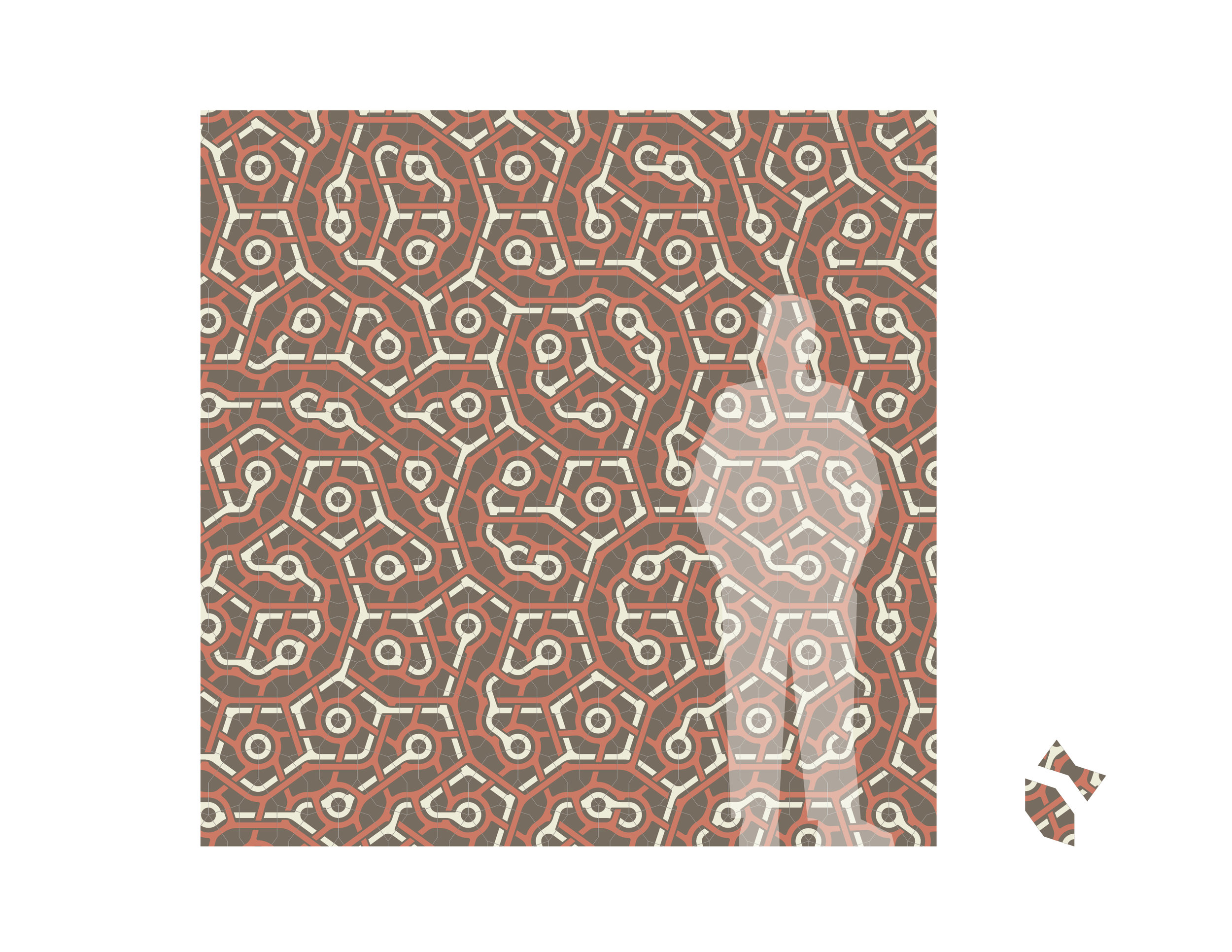

GIRIH ENCAUSTIC CEMENT TILE

Is it possible to create a tile with a pattern that never repeats?

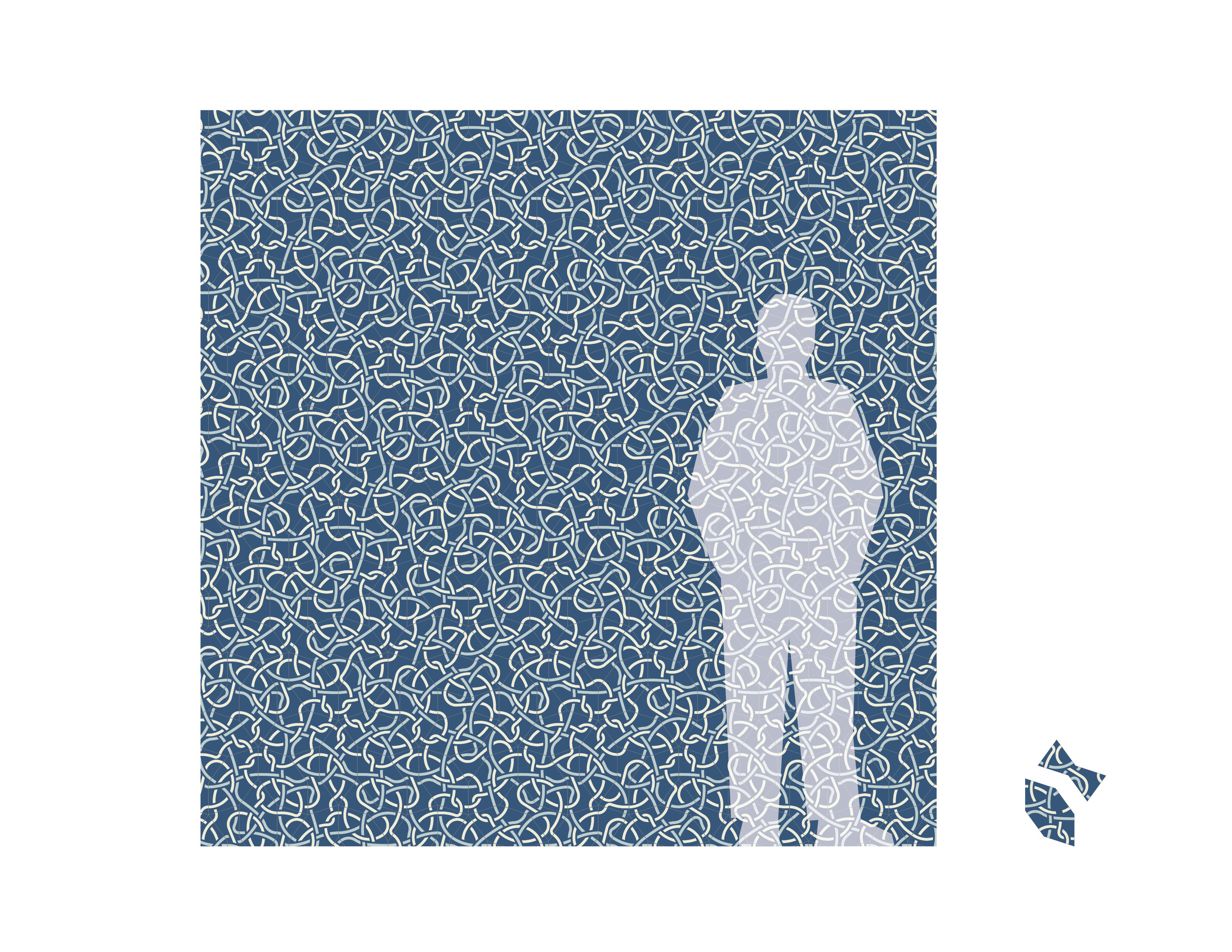

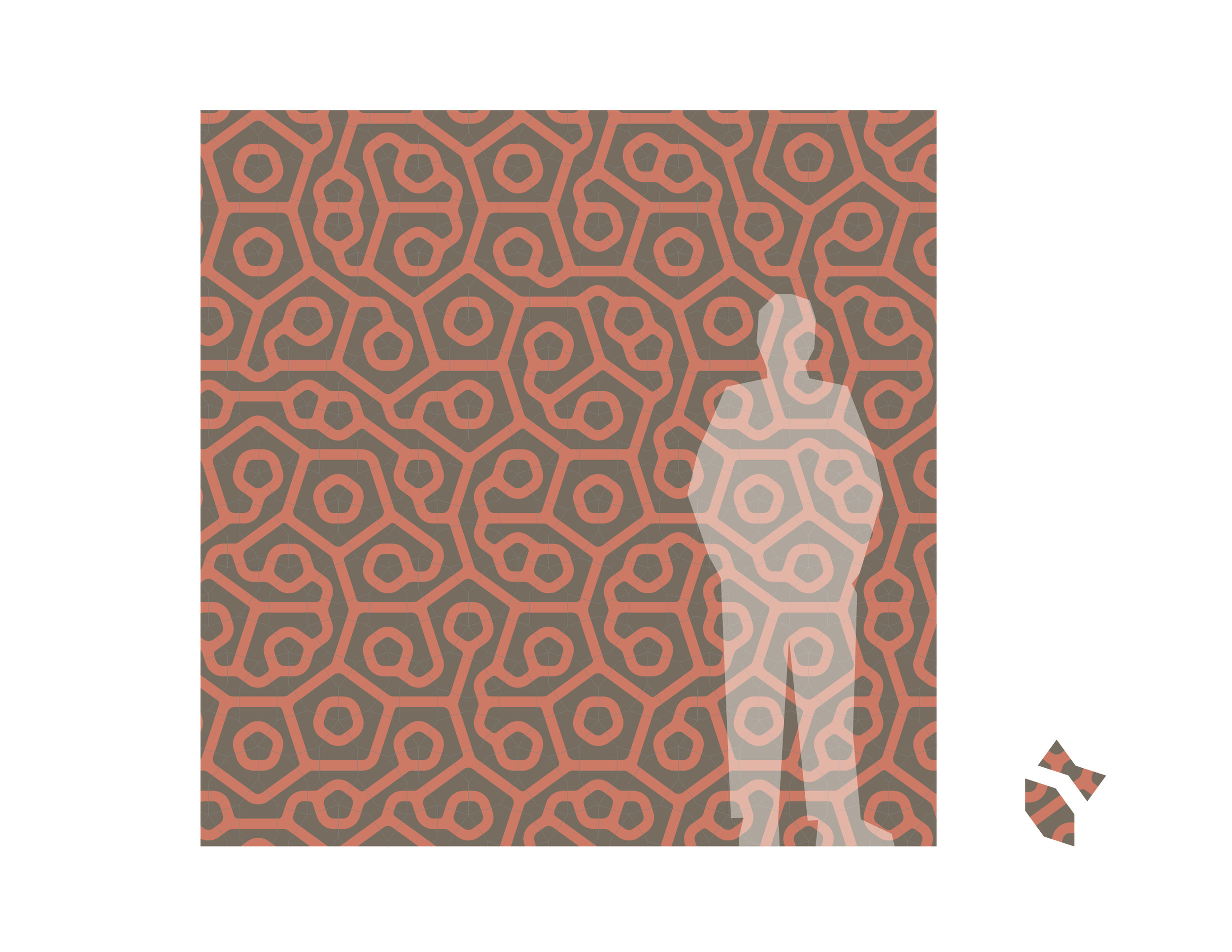

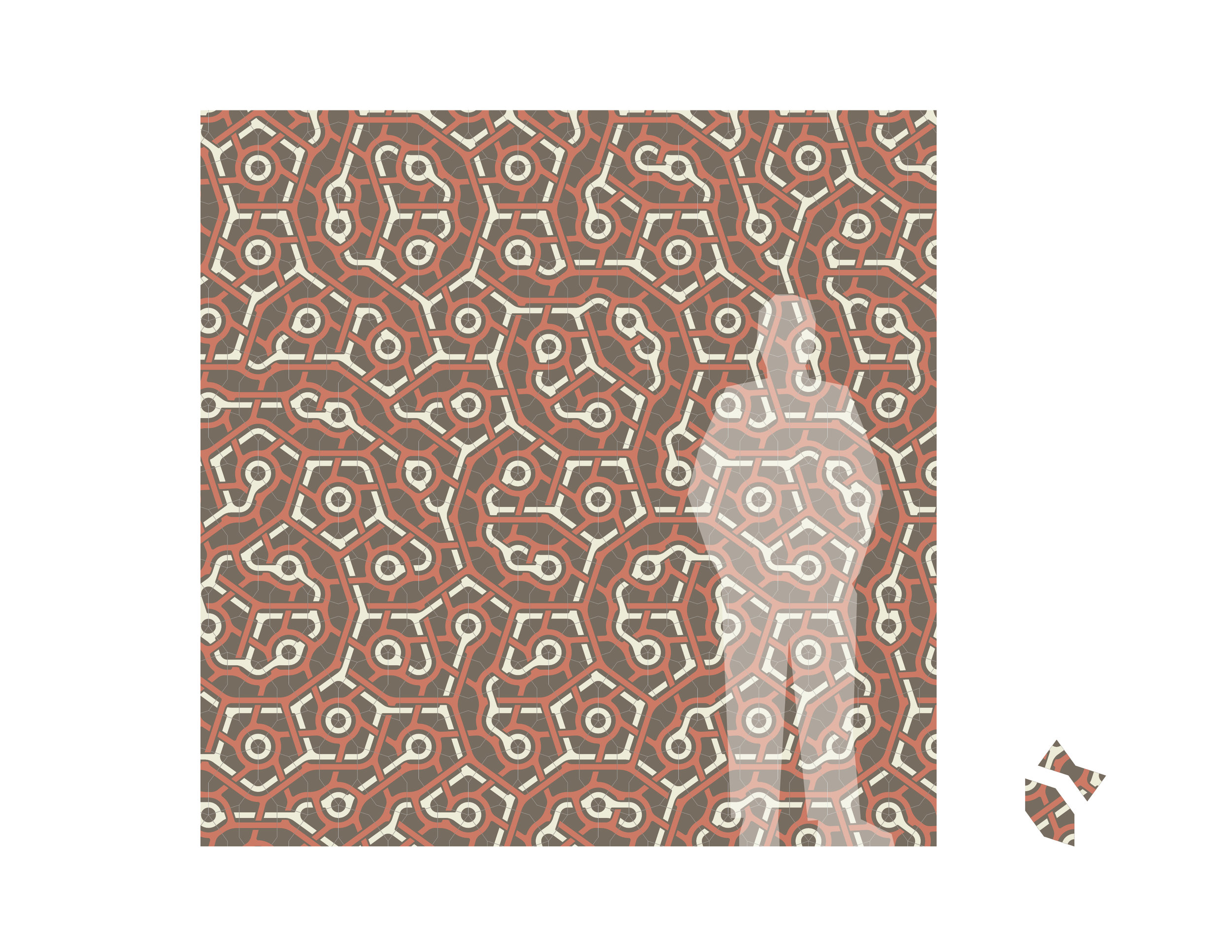

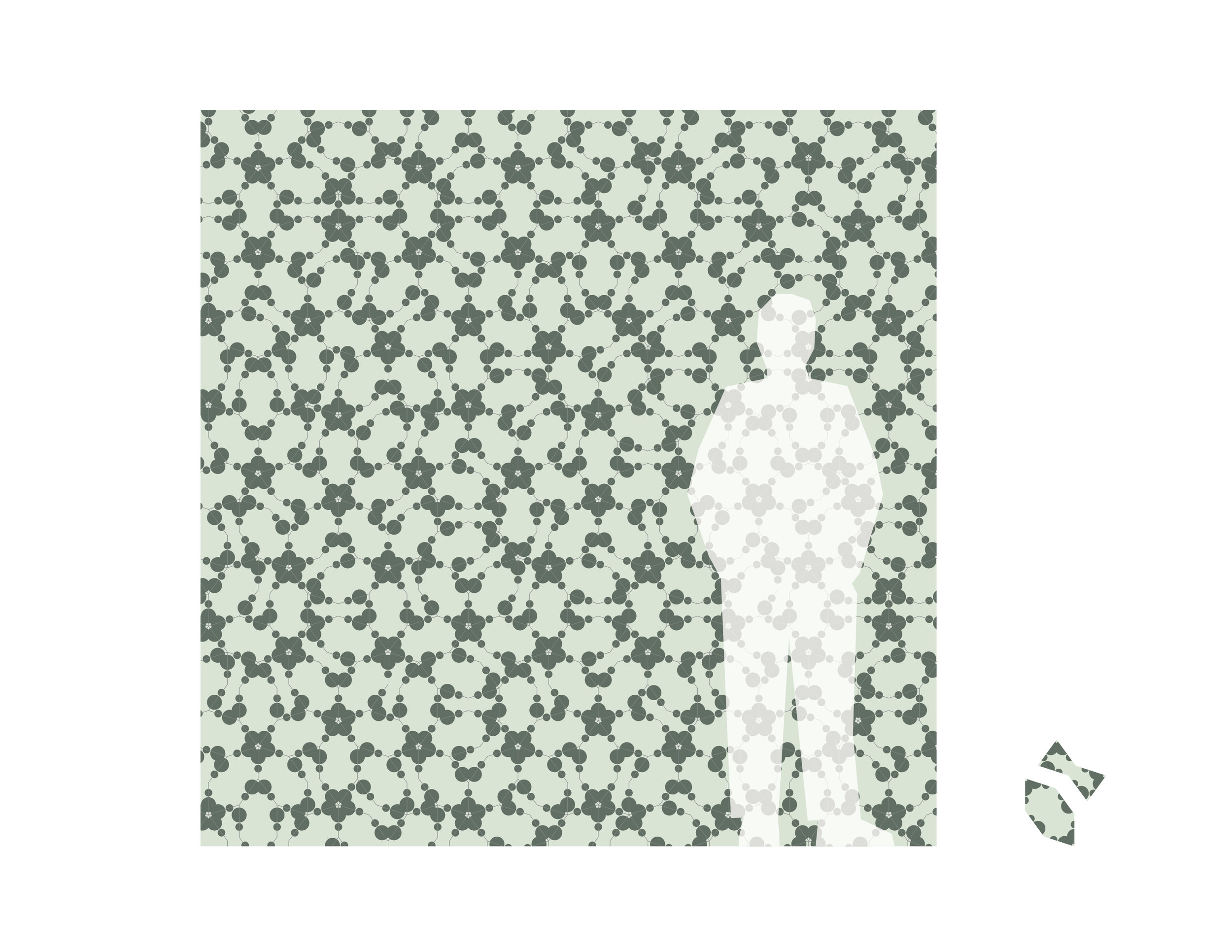

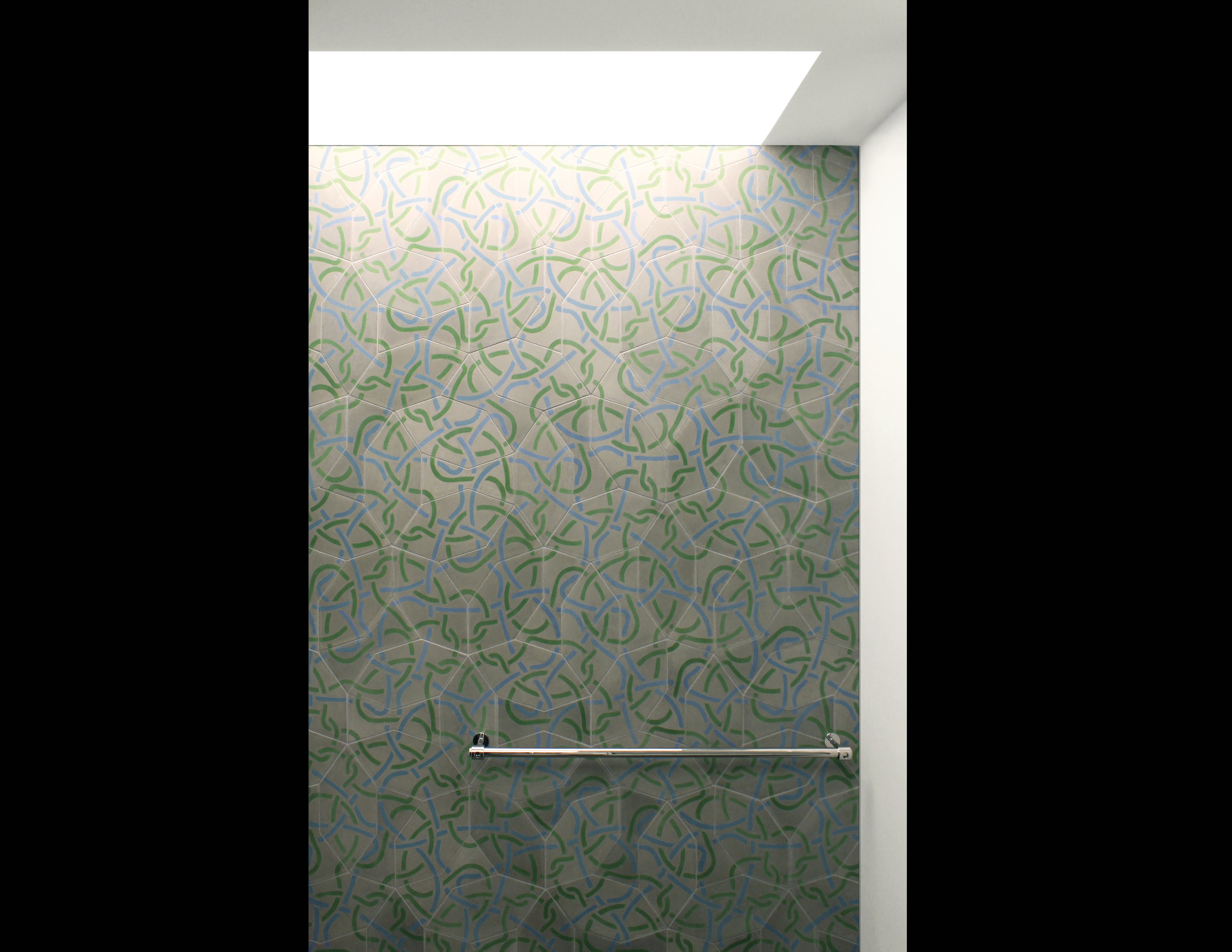

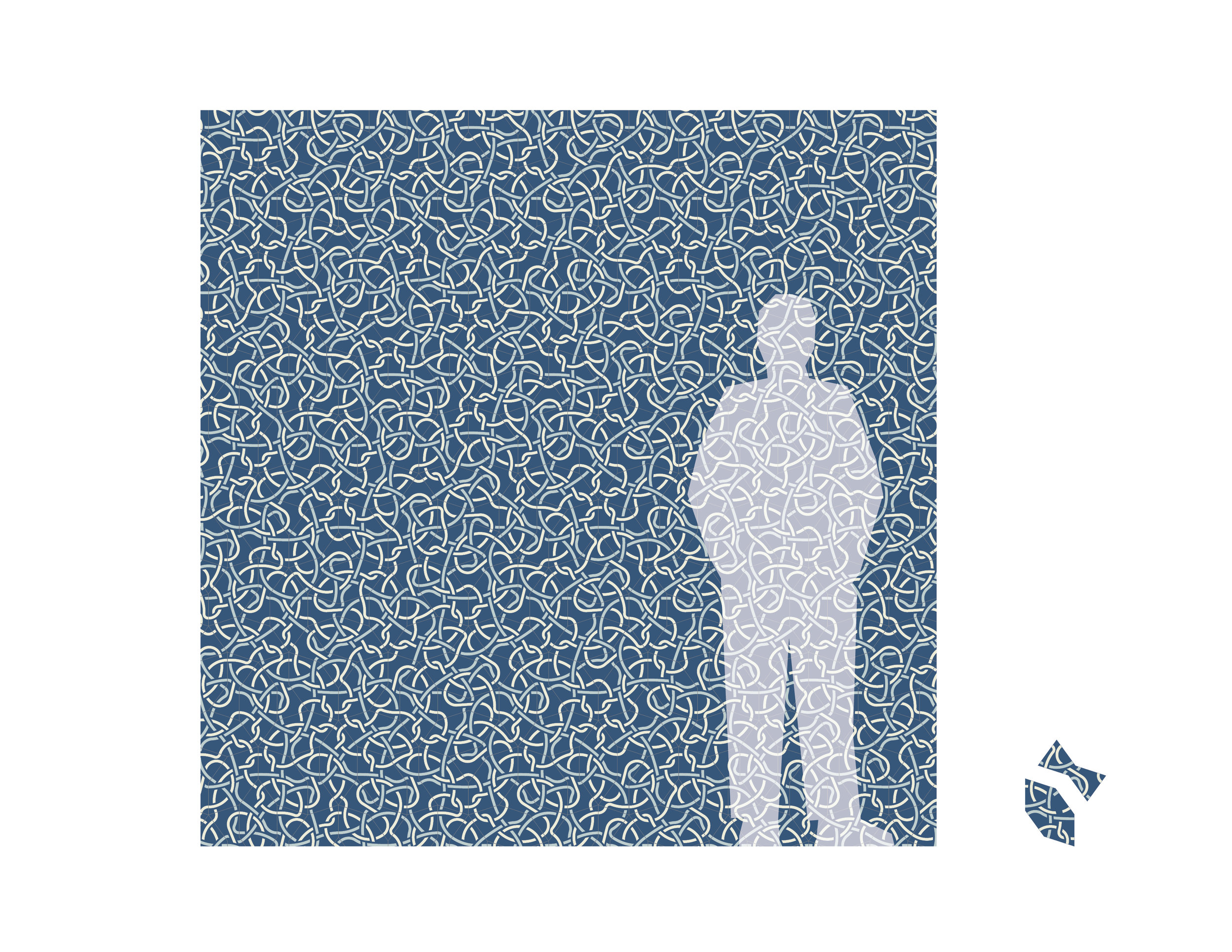

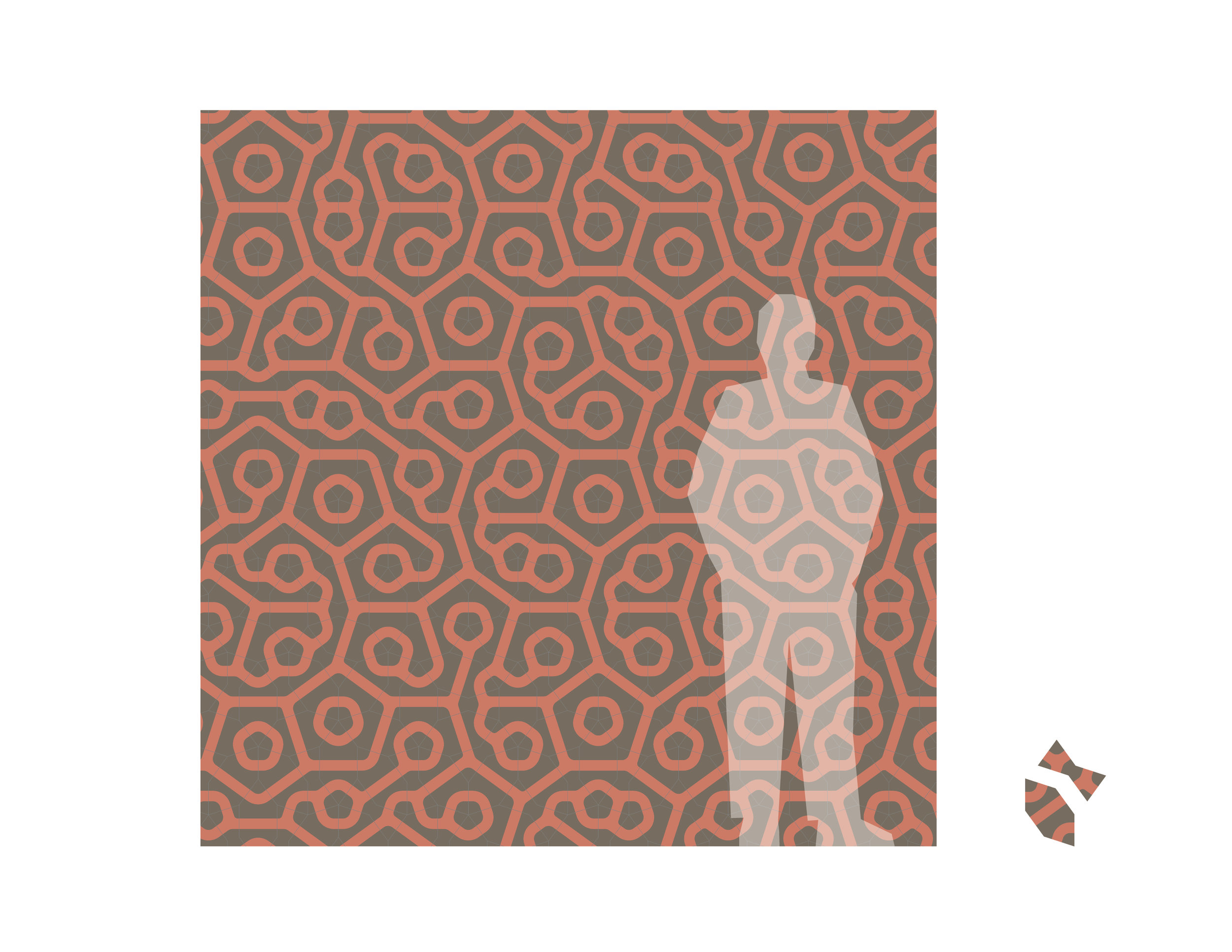

BSC designed a new range of cement tiles inspired by recent research connecting the complex patterns of medieval Islamic tiling with contemporary mathematical theory. Two special shapes drawn from ancient Islamic geometry are the basis of these new patterns - a hexagon and a bowtie – upon which are inscribed new aperiodic patterns developed by the architects. Every installation becomes unique as the pattern extends infinitely without repetition using just two tiles.

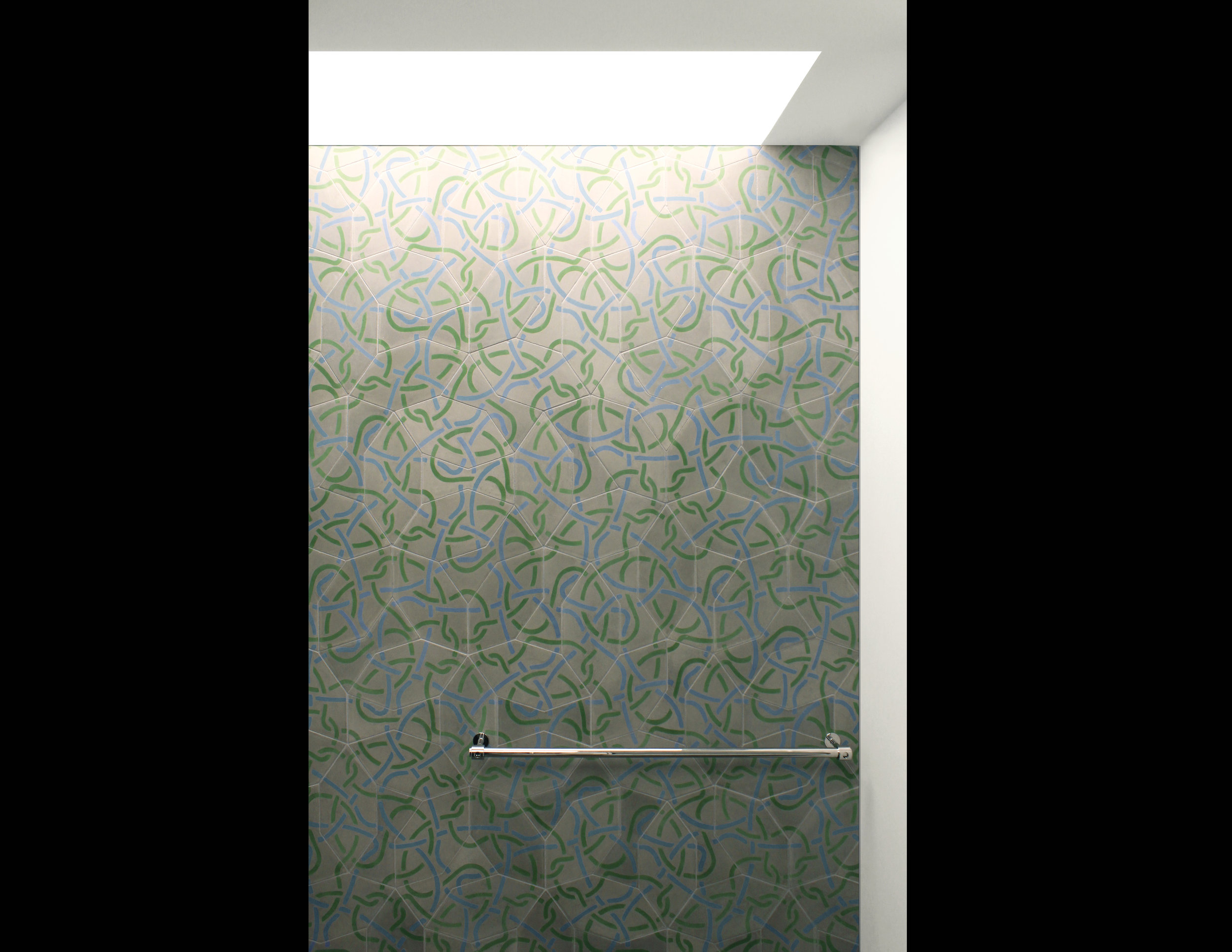

Fabricated in Morocco using a traditional encaustic technique, the tiles are crafted with dry pigments and portland cement, giving the surface its characteristic softness and coloration. Because the tiles are formed under pressure rather than fired, shrinkage is minimal and hairline grout joints can be achieved. The pattern extends through the body of the tiles, which allows for sanding or buffing in the field to eliminate minor surface imperfections.

The tiles are offered in twelve patterns in custom colors. Each order is site-specific, with a unique layout generated using a software app developed by the architect. Detailed layout drawings are shipped with the order to facilitate installation.

PROJECT TEAM:

Design: Bade Stageberg Cox (Timothy Bade, Jane Stageberg, Martin Cox, Andrew Skey)

Manufacturer: Popham Design

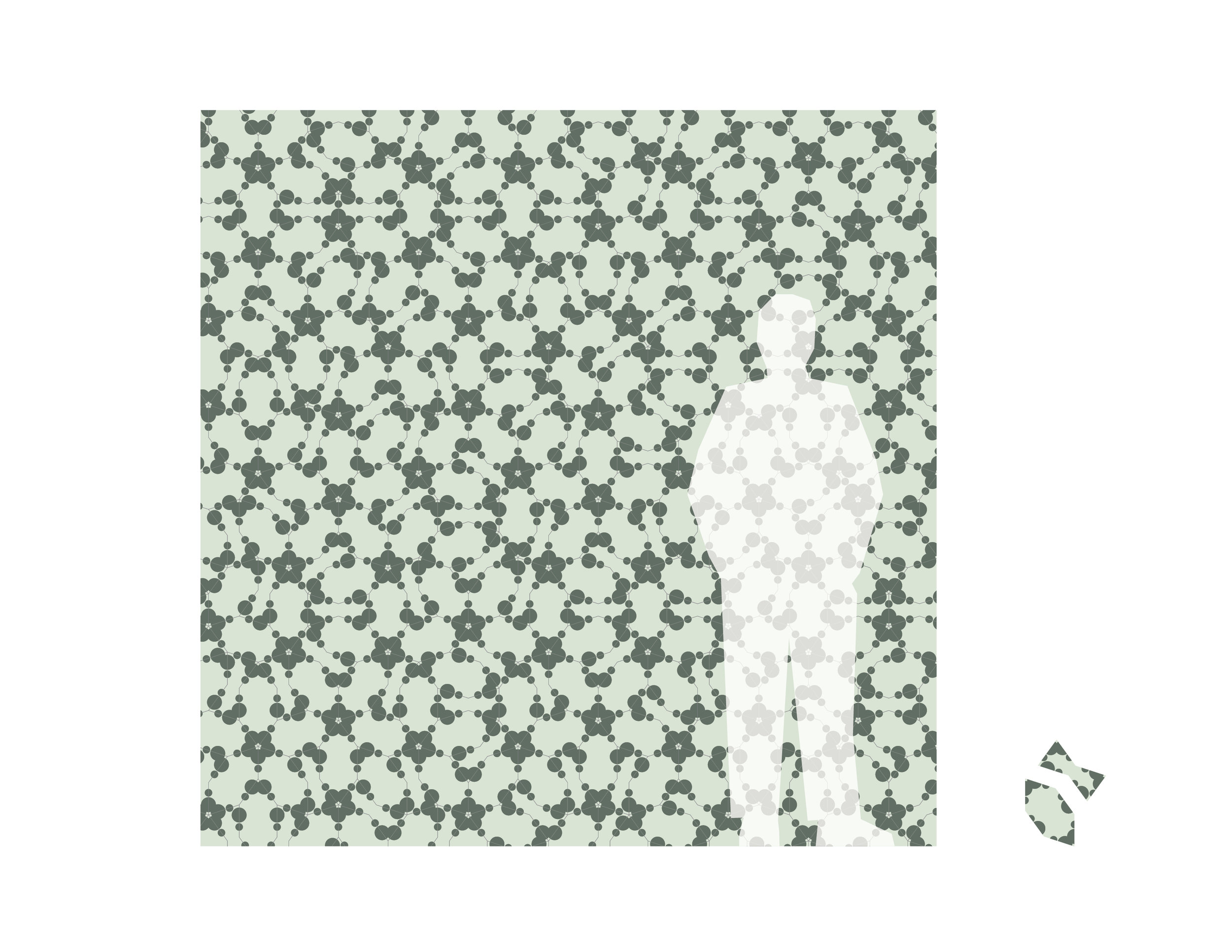

GIRIH, Encaustic Cement Tile

Is it possible to create a tile with a pattern that never repeats?

This new range of cement tiles is inspired by recent research connecting the complex patterns of medieval Islamic tiling with contemporary mathematical theory. Two special shapes drawn from ancient Islamic geometry are the basis of these new patterns - a hexagon and a bowtie – upon which are inscribed new aperiodic patterns developed by the architects. Every installation becomes unique as the pattern extends infinitely without repetition using just two tiles.

Fabricated in Morocco using a traditional encaustic technique, the tiles are crafted with dry pigments and portland cement, giving the surface its characteristic softness and coloration. Because the tiles are formed under pressure rather than fired, shrinkage is minimal and hairline grout joints can be achieved. The pattern extends through the body of the tiles, which allows for sanding or buffing in the field to eliminate minor surface imperfections.

The tiles are offered in twelve patterns in custom colors. Each order is site-specific, with a unique layout generated using a software app developed by the architect. Detailed layout drawings are shipped with the order to facilitate installation.

PROJECT TEAM:

Design: Bade Stageberg Cox (Timothy Bade, Jane Stageberg, Martin Cox, Andrew Skey)

Manufacturer: Popham Design